E-mail:info@enameled-wires.com

Tel/WhatsApp:+0086 19053473097

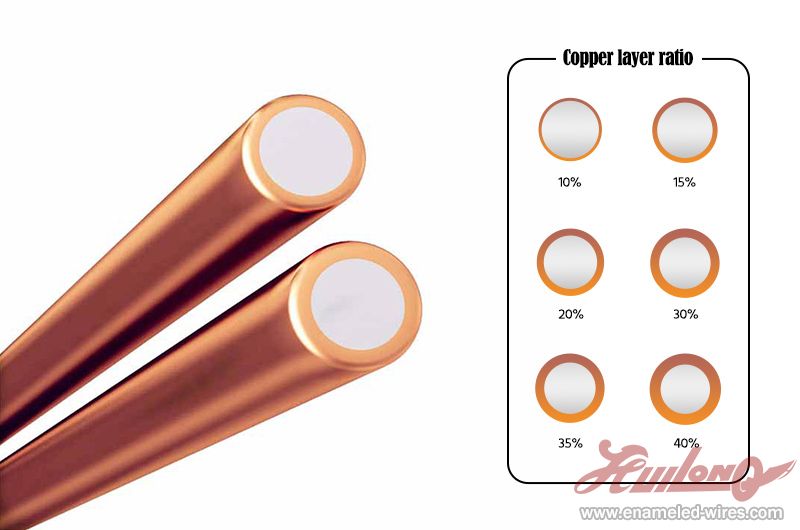

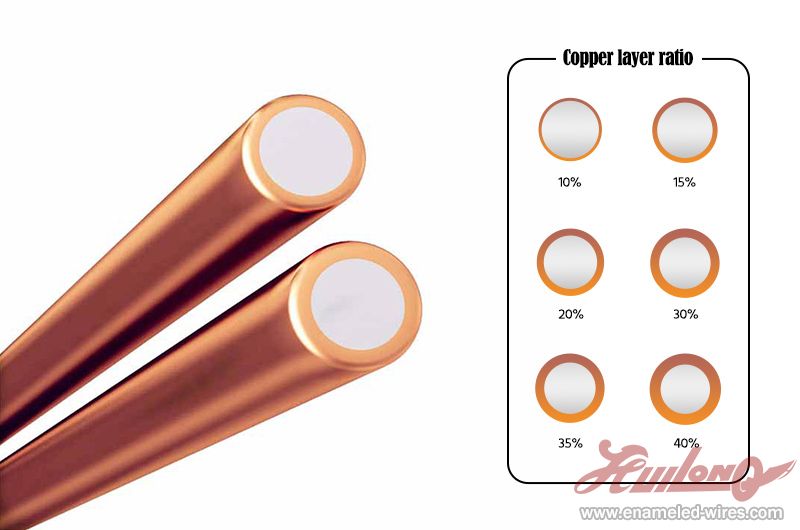

La superficie del alambre esmaltado de aluminio revestido de cobre es brillante, lisa y libre de defectos. Combina la alta conductividad eléctrica, resistencia, densidad y ductilidad del cobre con las ventajas del aluminio, como su ligereza y facilidad de procesamiento. Al mismo tiempo, es más económico que el alambre esmaltado de cobre puro y tiene un peso más ligero.

Rango de diámetro (mm): 0,05-8,0 mm

Clase de temperatura: 130 (Clase B), 155 (Clase F), 180 (Clase H), 200 (Clase C)

Grado de espesor de película: Grado 1, Grado 2, Grado 3

Dureza: Blanda (Clase A) y Dura (Clase H)

Proporción de capa de cobre: 10%, 15%, 20%, 30%, 35%, 40%

Proceso de revestimiento de cobre: Revestimiento CCA, CCA electrolizado

Estándar: IEC 60317-15, NEMA MW 1000:2016, GB/T 6109.15-2008, JIS C 3202:2017

Certificación: UL, SGS, ROHS, ISO

Color: Color natural, rojo, azul, verde, etc.

Paquete: PT-10, PT-25, PT-30, PT-60, bobina de madera de 30 kg/50 kg, o según los requisitos del cliente

Rango de diámetro (mm): 0,05-8,0 mm

Clase de temperatura: 130 (Clase B), 155 (Clase F), 180 (Clase H), 200 (Clase C)

Grado de espesor de película: Grado 1, Grado 2, Grado 3

Dureza: Blanda (Clase A) y Dura (Clase H)

Proporción de capa de cobre: 10%, 15%, 20%, 30%, 35%, 40%

Proceso de revestimiento de cobre: Revestimiento CCA, CCA galvanizado por electrólisis

Standard: IEC 60317-15, NEMA MW 1000:2016, GB/T 6109.15-2008, JIS C 3202:2017

Certificación: UL, SGS, ROHS, ISO

Color: Color natural, rojo, azul, verde, etc.

Paquete: PT-10, PT-25, PT-30, PT-60, carrete de madera de 30kg/50kg, o según los requisitos del cliente

The copper cladding ratio in Copper-Clad Aluminum (CCA) enameled wire is typically between 10% and 20%. A higher copper content may compromise the balance between conductivity and cost-effectiveness.

If customers require enameled copper-clad aluminum wire with a higher copper content, please contact us for customization.

Purchasing guide for enameled copper-clad aluminum wire